Rubber Foam Material Introduction

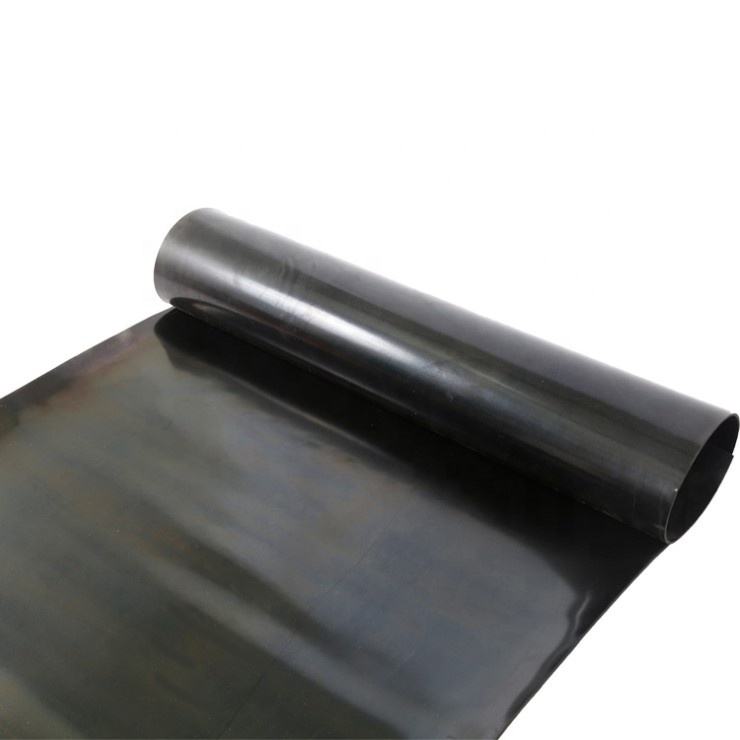

Rubber foam material, also known as rubber sponge, microporous rubber or foam rubber, is composed of a continuous solid phase (matrix rubber) that constitutes the material itself and a fluid phase (pore) that forms pores. According to whether the hole is connected, it can be divided into open cell foam material, closed cell foam material and mixed cell foam material. Foamed rubber can save rubber resources by appropriately increasing the volume of the bubble hole, and obtain the characteristics of high compression and softness that are not found in general vulcanized rubber, so as to maximize the function of rubber.

The properties and uses of rubber foam products are largely determined by the raw rubber.

Natural rubber (NR), butadiene rubber (BR) less odor, often used in the manufacture of daily necessities;

Styrene-butadiene rubber (SBR) has good wear resistance and is mostly used for sole materials;

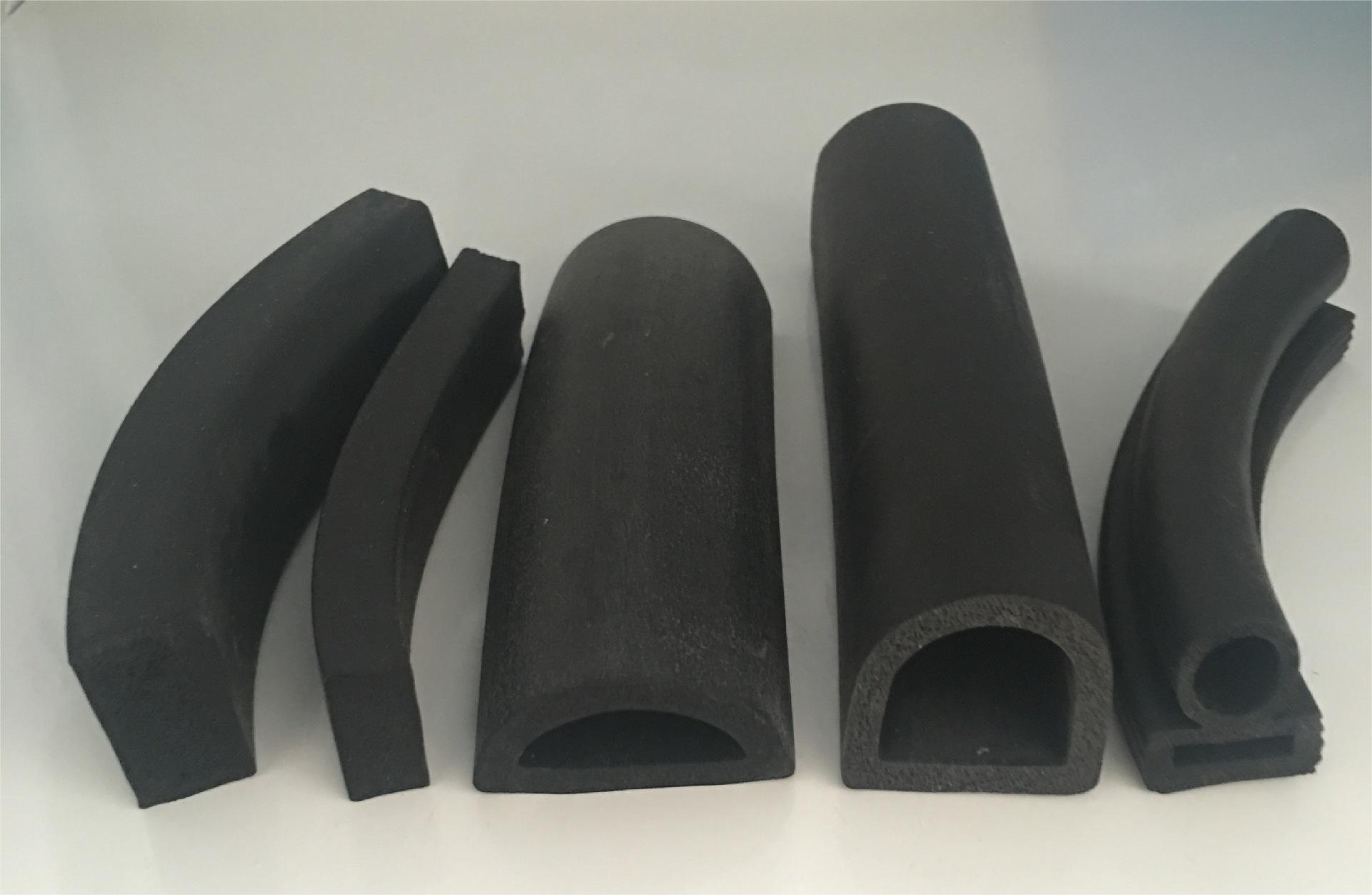

EPDM (ethylene propylene diene Diene rubber) is often used in the manufacture of automobile sealing strips, sealing rings, heat insulation products because of its ozone resistance, heat resistance, weather resistance, low softness and soft properties.

Nitrile butadiene rubber (NBR) has good oil resistance, heat resistance and resilience, and is widely used as a decrease shock material for automotive engines.

Silicone rubber can withstand the high temperature of 300 ° C, used for sealing materials, expansion connection materials in special environments, heat insulation, vibration absorption materials and so on.